Are chips in your stone benchtop trapping food and liquid?

The Marble Man specialises in stone benchtop repairs to kitchen benchtops, bathroom vanities, countertops, barters and tables. Natural marble, limestone, travertine, onyx, granite and engineered Caesarstone, Essastone, Quantum Quartz, Silestone and HanStone are strong materials however they are still susceptible to chips, cracks and stains.

Damage is often caused by an accidental impact from a saucepan or a plate, and if not fixed can cause more serious problems.

Moisture can penetrate the stone causing it to discolour and stain. Chips and cracks can be sharp and dangerous and can compromise the strength of the stone.

Professional stone benchtop chip repairs are essential to preventing further damage. Do not attempt to repair a chip with super glue as this will create further damage to the stone.

Marble Benchtop Chip Repairs

- Stone benchtop repairs on marble involves the use of epoxy resins with added colour pigments to match the stone

- The resin hardens inside the chip and is then polished or honed to blend in with the existing surface

- Sometimes a UV light is used to harden the resins

Engineered Stone Benchtop Chip Repairs

- Stone benchtop repairs on engineered stone benchtops involves filling the chips and cracks in the stone with coloured UV glues and resin

- UV light technology is used to harden the material in the chip

- The area is then polished smooth to match the original finish of the stone benchtop, countertop, vanity or table

EMAIL OR CALL US NOW! 1300 627 626

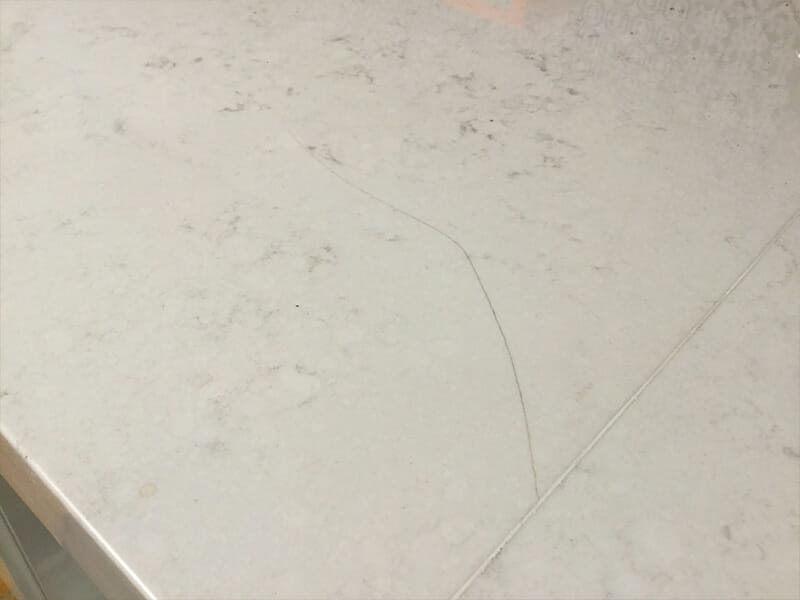

Are cracks compromising the strength of your stone benchtop?

Cracks can occur in all natural marble, granite and engineered stone benchtops for many reasons. Natural marble, travertine, limestone, granite and engineered stones such as Caesarstone, Essastone, Quantum Quartz and Silestone can crack due to movement in a building, heat from a dishwasher under a benchtop or weight of a person standing on a benchtop or countertop.

This type of cracking can compromise the strength of the stone. It must be repaired immediately to avoid further cracking and moisture entering the stone benchtop. Dirt and liquid build up in a crack can cause irreversible discolouration and staining.

Benchtop Crack Repair Process

- If the stone has dropped on one side of the crack, the stone benchtop will be lifted and clamped

- The stone benchtop will be reinforced by glueing an aluminium bar to the underside of the benchtop so it is not visible

- Natural marble, limestone and travertine benchtops are repaired using a different method to engineered stone benchtops

- Epoxy resin and coloured pigments are applied to the crack in a marble or natural stone benchtop and left to harden

- Coloured UV glue and resin are applied to the crack repair in an engineered stone benchtop

- The crack repair materials in both types of stone are hardened using UV light technology

- The stone benchtop is then polished or honed to match the existing finish of the benchtop

Do not attempt to repair a crack with super glue or similar. This will damage the stone even further.

Professional stone benchtop crack repairs, in most cases are undetectable and can prevent replacement.

EMAIL OR CALL US NOW! 1300 627 626

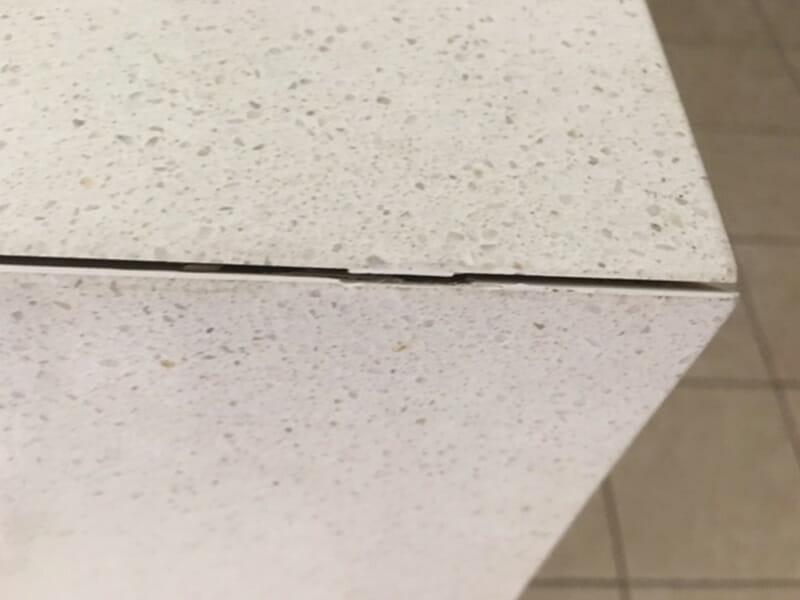

Have the joints on your stone benchtop become loose?

Stone benchtop repairs to joints are common on natural marble, limestone, travertine, onyx, granite and engineered Caesarstone, Essastone, Quantum Quartz, Silestone and HanStone kitchen benchtops, bartops, table tops and bathroom vanities.

Over time and with daily use, stone benchtop joints can loosen compromising the strength of the benchtop. When this occurs the loose or cracked joints allow food and liquids to penetrate causing staining and discolouration. On light coloured benchtops where the resin in the joint is pale it can over time detract from the overall look of the stone benchtop as the resin can yellow.

A shift in the benchtop and loosening of the joints can also be caused by building movement. Constant vibration can loosen the resin.

Age of the resin and incorrect maintenance can also cause loosening, staining and discolouration of the joint.

Joint Repair Process

- Existing, damaged epoxy resin in natural and engineered stone bechtops is removed using a special tool

- The joint is clamped if possible and reinforced by glueing an aluminium bar to the underside of the benchtop so it is not visible

- A solvent is used to clean the joint before the epoxy resin and coloured pigments matching the benchtop colour are added

- Once the epoxy resin has hardened it is polished or honed to match the exiting finish of the stone kitchen benchtop, bathroom vanity or bartop

- The new joint will look clean and undamaged leaving the stone benchtop, vanity or bartop protected, strong and attractive

EMAIL OR CALL US NOW! 1300 627 626

Does the engineered or natural stone in your kitchen or bathroom need stain removal?

Natural and engineered stones in kitchens and bathrooms are susceptible to staining from a number of sources. These stains are unable to be removed with even professional cleaners. They require specialised attention and t be treated with processes that will penetrate and draw the stains out.

Over many years The Marble Man has developed a number of processes to remove stubborn stains from natural and engineered stones. Through trial and error, research and development, we have created a number of poultices to remove yellowing from engineered kitchen benchtops, yellow and brown stains from natural shower tiles, vanities and toilet surrounds and dark oil stains from natural stone benchtops and floor tiles.

Engineered stones that The Marble Man can remove stains from

Engineered stone such as Caesarstone, Essastone, Silestone, Quantum Quartz, HanStone, Neo Stone are popular choices for kitchen benchtops and island benches. These are quite hard stones, however over time, when incorrect cleaners are used, they can develop yellow patches or an overall yellow tone.

Natural stones that The Marble Man can remove stains from

Natural stone shower tiles, vanities and toilet surrounds made from marble, travertine, limestone and onyx are susceptible to yellow and brown stains when water leaks under the tiles. Moisture causes the iron content in the stone to rise up to the surface of the stone causing the discolouration.

The processes used to remove stains

The Marble Man has developed the following poultices to remove stains from engineered and natural stones:

More information on each of these processes can be found on the links above. The Marble Man also has a Stain Repair Gallery to show examples of how each of these processes has revived natural and engineered stone surfaces, avoiding replacement.

The Marble Man technicians will ensure your natural and engineered stone surfaces are treated with care, when removing yellowing and stains.

EMAIL OR CALL US NOW! 1300 627 626

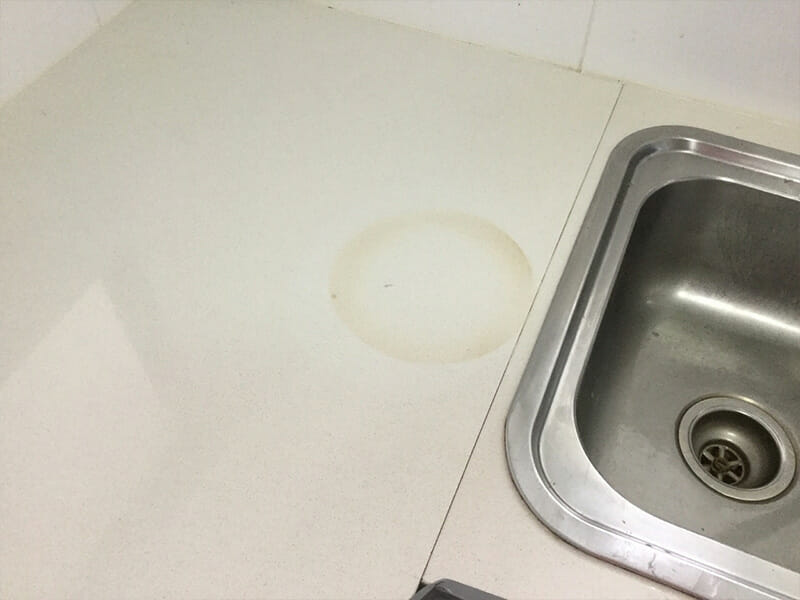

Has a hot pot left a ring burn on your Caesarstone kitchen benchtop?

Hot pots left for too long, on engineered benchtops such as Caesarstone, Essastone, Quantum Quartz and Silestone, can cause yellow to brown marks that can not be removed by cleaning. These can often be described as brown stains but are in fact burns.

When hot pots or saucepans are placed directly on the benchtop surface and left there for more than a few minutes, this can cause the resin in the engineered stone to burn and discolour. These burn marks can occur on all stone surfaces but will appear differently on each surface. On light coloured stones the burn will appear as a dark mark, and on dark coloured stone it will appear as a light coloured stain.

If left on long enough the stone benchtop can become so hot that thermal expansion can occur in the hot area, causing the stone to crack. This can even cause a very loud bang like a gun going off when it occurs.

Burn marks on marble benchtops can appear brown or white but mainly white. The white colour is caused by the natural mineral crystals under the surface, popping.

Burn marks on granite benchtops often appear lighter in colour as the crystals in the stone pop under the surface like marble.

How burn marks are removed

To remove the burn marks, the surface of the stone must be ground to below the depth of the burn mark, which can often be quite deep. If not completed correctly this can sometimes leave a significant dip in the surface of the stone, which can change the reflection.

- The Marble Man grinding process involves using specialised machinery to feather or blend out the dip created from the burn removal, to minimise the change in the reflection

- The technician will then grind the stone with higher grade abrasives, to remove the scratches created by the grinding process

- The final part of the process we use our unique process called Fusion Polish which is only used on engineered stone to match the existing finish on the stone benchtop

EMAIL OR CALL US NOW! 1300 627 626

Has bleach or acid from a battery left a patch on your stone benchtop?

Engineered stones such as Caesarstone, Essastone, Quantum Quartz, HanStone and Silestone are made up of around 95% quartz crystals and 5% resin. This break up varies slightly depending on the brand of stone.

When the resin in the engineered stone comes into contact with caustic substances like oven cleaner, drain cleaner and very strong acids such as battery acid, the chemicals bleach the stone causing a light patch. If you look closely at the damage you can see that the bleach changes the colour of the resin only and the quartz granules remain the same colour as the original stone.

Why caustic substances damage stone

- There are several reasons why damage is caused to stone benchtops from caustic substances:

- No protection is placed on the benchtop under caustic chemical bottles

- Overspray from oven cleaner sprayed onto oven trays and racks directly on the benchtop

- Drain cleaning products such as ‘Draino’ being spilled on the bathroom vanity around the sink

- Chemical bottles are placed onto the stone surface and drips form after pouring the substance

- The laundry benchtop is splashed with bleach when washing

How to remove caustic bleach stains

Caustic stains can only be removed by polishing. The Marble Man has developed a special process to do this on engineered stone benchtops called a Fusion Polish. There are some important considerations when having a bleach stain removed.

- The first part of the process is to grind the surface of the stone down below the base of the beached resin

- This can create a significant dip in the benchtop reflection if not done correctly by a trained technician

- The use of specialised polishing equipment at this stage is imperative to ensure the dip is keep to a minimum

- After grinding past the caustic burn mark the stone is then honed to remove the heavy grinding scratches

- A final Fusion Polish is carried out to restore the original look and feel to the engineered stone benchtop

EMAIL OR CALL US NOW! 1300 627 626

Is your marble bathroom vanity etched from acidic dyes and toiletries?

Etch marks mainly occur on marble benchtops, vanities and bartops. They are deep crevices in the stone, formed when acidic substances eat into the surface. Common liquids that etch marble and other soft stones such as limestone, onyx and travertine, are lemon and orange juice, wine, acidic foods and acidic cleaners.

When an etch mark first occurs it appears lighter in colour to the usual stone colour. The darker the stone the more obvious the etch mark. Etch marks on dark stone will look greyish in colour.

Over time, if left, etch marks will accumulate dirt and allow liquids to penetrate deeper into the stone’s surface, damaging and staining the stone. It is important to have etch marks polished or honed as soon as possible to avoid further damage.

How to remove etch marks

The Marble Man specialises in removing etch marks from marble benchtops. During the polishing or honing process we grind the stone, using a range of diamond abrasives and polishing compounds, to reveal a fresh, smooth surface and a uniform finish.

After polishing or honing, the surface is cleaned and treated with an anti-bacterial formulation. After it is completely dry it is sealed with a penetrating sealer, to prevent staining. Note that a sealer will only help protect the stone from staining.

How to protect stone from etching

For total protection from etching, we recommend Tuffskin. This is a new form of sealing using a protective film. Tuffskin is mainly used on marble, travertine, limestone and onyx benchtops. It will not allow any substances to penetrate and is the only way to protect your stone from etching.

Please visit our benchtop polishing page for more information on polishing and honing. Visit our Sealing page and Tuffskin page for more information on penetrating sealers and Tuffskin application.

If you need further information on how The Marble Man can repair your etched benchtop, please send your details and upload your photos via our contact page, or call us today.

EMAIL OR CALL US NOW! 1300 627 626

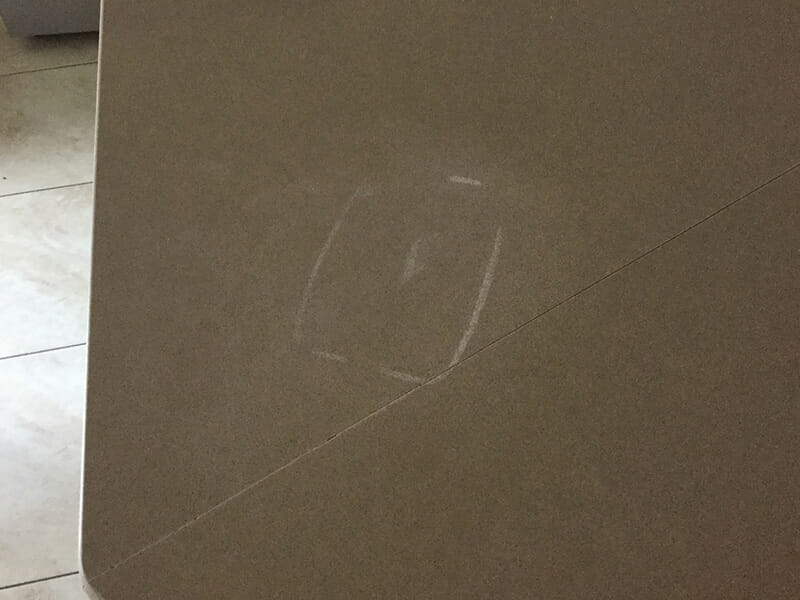

Is your marble benchtop scratched from items being dragged over the surface?

Cuts and scratches on natural marble and engineered stone benchtops, vanities and bartops can not only look unattractive, they can damage the stone. Left untreated these fine lines can attract dirt and moisture and stains can develop.

The only way to remove cuts and scratches is to repolish or hone the stone. The Marble Man is experienced at identifying the exact treatment needed for each type of stone and can successfully restore the stone surface.

Causes of cuts and scratches

Scratches on natural and engineered stone benchtops can develop for many reasons:

- Damage can occur during installation or during building or renovating

- Using a knife to cut directly on the surface of the benchtop and not using a cutting board

- Dragging items such as cups and plates across the surface of the benchtop

Different polishing processes

Natural marble requires a different polishing process to granite or engineered stone.

Polishing or honing will remove scratches on marble benchtops. This involves the use of diamond abrasives to wet polish the stone which reveals a fresh layer of stone. More information on marble polishing can be found in the polishing section.

Granite is a very hard stone and does not scratch as easily as marble, but it can still scratch. It has traditionally been difficult to polish, however The Marble Man has developed a special process called Fusion Plus Polish to remove scratches and dull patches. Whilst the process has some success results will depend on the extent of the damage.

Engineered stone made from quartz is also hard and not easily polished. The Marble Man has developed a similar process called Fusion Polish to successfully restore engineered stone surfaces.

EMAIL OR CALL US NOW! 1300 627 626

MASTER BUILDERS QLD MEMBER

HIA QLD MEMBER

TUFFSKIN APPROVED APPLICATOR

AQUAMIX APPROVED APPLICATOR

DRYTREAT APPROVED APPLICATOR