General Information on Natural Stone

Natural stones used to make granite kitchen benchtops, marble bathroom vanities, travertine floor tiles, onyx furniture, sandstone pavers and much more, are formed underground and are classified as sedimentary, igneous and metamorphic. These stones are unique, beautiful and stylish because of their natural colour and patterning and because of the durability of some of the stones such as granite. No two natural stones are the same, which is what makes it such a sought after building material.

Natural marble, granite, limestone, sandstone, onyx and travertine are popular choices in home renovation and building, for kitchen benchtops, bartops, bathroom vanities, shower floors and walls, living room floor tiles, tables, ornaments, outdoor pavers and pool surrounds. In a commercial setting these precious stones are perfect for hotel foyers, reception desks, opulent suites and penthouses, resort pool areas and office buildings with high traffic entrances.

These natural stones are popular with high end interior designers and architects as they hold their value, look prestigious and come in a variety of browns, blacks, greens, whites, creams, yellows and reds, making design options endless.

Sedimentary stones include limestone, travertine and sandstone. These stones are formed when organic matter accumulates and consolidates in layered deposits at the bottom of lakes and in the sea. Over millions of years the layering causes the weight of the rock beds to increase. Eventually the pressure produces a chemical reaction that causes the sediment to harden and turn into stone. Most sedimentary stones are rated around a 3 on the Mohs Scale of hardness.

Igneous stones include granite, basalt and obsidian. These stones are exposed to extreme heat hence the name ‘igneous’ which means fire. The stone is formed underground where rock located up to 40km under the earth’s surface melts at temperatures of up to 900°c and becomes magma. The magma rises and cools slowly trapping gases and minerals and eventually solidifies into stone that has large crystals and a course texture. Most metamorphic stones are rated around a 6-7 on the Mohs Scale of hardness.

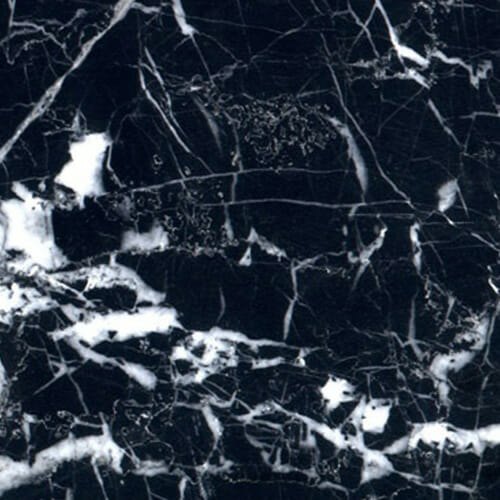

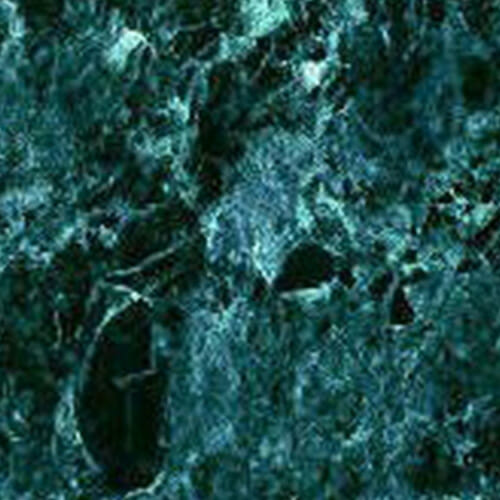

Metamorphic stones commonly used in building are marble, onyx and serpentine. These stones are formed when existing igneous and sedimentary rock is buried deep below the earth’s surface and exposed to extreme heat and pressure over millions of years. They are called metamorphic because “meta” means change and “morph” means form and that is what it does – the rock changes its composition, texture and colour. Most metamorphic stones are rated around a 3-4 on the Mohs Scale of hardness.

General Information on Engineered Stone

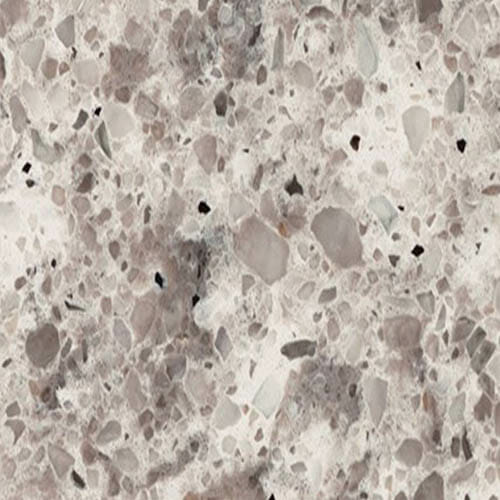

Engineered stones also known as agglomerate, manufactured stones, man made stones or reconstituted stones, are made from a combination of approximately 7% resins, cement, and coloured pigments and upwards of 93% natural stone chips such as quartz or marble. These materials are bound together to make a slab. Engineered stones are designed to emulate natural stones such as marble and granite and are an extremely popular alternative to natural stone in building today.

Some of the engineered stone brands include Caesarstone, Essastone, Quantum Quartz, Silestone, Smartstone and HanStone. These stones are similar in composition, varying only by a few percent in total quartz used. Their differences lie in the colours, patterns and applications offered. Some engineered stones are just made for benchtops whereas as others can be used for tiles.

The preference to choose engineered stone over natural stone is purely a personal one. Natural stone is attractive because of it’s unique inconsistencies in colour, texture and patterns, however engineered stones are more consistent in colour and patterning. There are many reasons why engineered stones are being chosen over natural stone:

- Engineered stones are durable, scratch, stain and heat resistant *

- They come in a variety of colours and patterns

- Natural marble is susceptible to etching and staining, however a marble look can be created with the etch and stain resistant properties of granite, making it a good choice for high stress areas such as kitchen benchtop and bathroom vanities

- The quartz used in the engineered stones is a similar hardness to granite and rates a 7 on the Mohs Scale of Hardness

- It is easy to clean and will require less long-term maintenance like granite if cared for according to manufacturers instructions (It is only ‘resistant’ to scratching, staining and heat and therefore hot pots must not be left on for extended periods, cutting boards should still be used and spills cleaned up immediately as in the case of any natural stone)

* In our experience engineered stone kitchen benchtops and bathroom vanities do chip and scorch, however we have developed processes to repair even large chips making them virtually undetectable. We have also developed polishing processes to restore the factory finish to engineered stone surfaces damaged by heat. For examples of chip and burn repairs visit our Stone Benchtop Repair Gallery.

MASTER BUILDERS QLD MEMBER

HIA QLD MEMBER

TUFFSKIN APPROVED APPLICATOR

AQUAMIX APPROVED APPLICATOR

DRYTREAT APPROVED APPLICATOR